Bearing Roller Cylindrical components play a crucial role in various machines and vehicles. These rollers provide superior load distribution and reduce friction effectively. Many industries rely on them for both performance and reliability.

When choosing Bearing Roller Cylindrical types, several factors come into play. The material, design, and size significantly affect the efficiency of these components. For instance, steel rollers are common, but newer materials offer unique benefits. It's essential to evaluate the specific needs of your application. Sometimes, companies overlook the importance of proper selection.

This oversight can lead to performance issues. The wrong bearing type can cause early failure or excessive wear. Therefore, reflection on the right choices is vital. Understanding your requirements can enhance performance dramatically. In essence, we will explore various Bearing Roller Cylindrical types and their respective advantages in this discussion.

Cylindrical roller bearings (CRBs) play a crucial role in various applications. Their design allows for high radial load capacity and reduced friction. In electric motors, for instance, CRBs are used widely. The global market for cylindrical roller bearings is expected to exceed $10 billion by 2025, according to research data. This growth highlights their importance in modern engineering.

Different types of cylindrical roller bearings exist. For instance, single-row bearings are common in automotive applications. They provide efficient performance under high loads. Conversely, double-row bearings offer better stability in heavy machinery. Each type serves a specific need, but misapplications can lead to failures. It's vital to match the bearing type with the intended function.

In construction, CRBs are critical. They ensure machinery operates smoothly under extreme conditions. However, improper installation can compromise their effectiveness. A recent study noted that nearly 15% of bearing failures result from incorrect handling. Understanding the nuances in type selection and installation is essential for optimal performance.

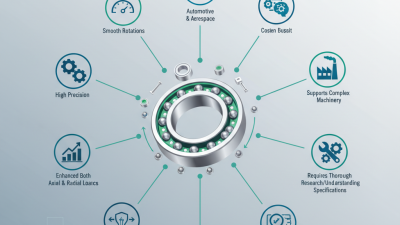

Cylindrical roller bearings are vital for efficient machinery. They consist of cylindrical rollers that help distribute load evenly. These bearings have several key characteristics that enhance their performance. The design allows them to carry heavy loads in a compact space.

One notable feature is the increased contact surface. This means lower stress concentrations and better load handling. However, this can also lead to a shorter lifespan if not properly maintained. Regular checks for wear and tear are crucial. Some users overlook this and face unexpected failures.

Another characteristic is their ability to accommodate misalignment. While this provides flexibility, it may also cause uneven wear if the misalignment exceeds limits. Using these bearings requires a balance between operational demands and maintenance. Users should be aware of these trade-offs to ensure long-term reliability.

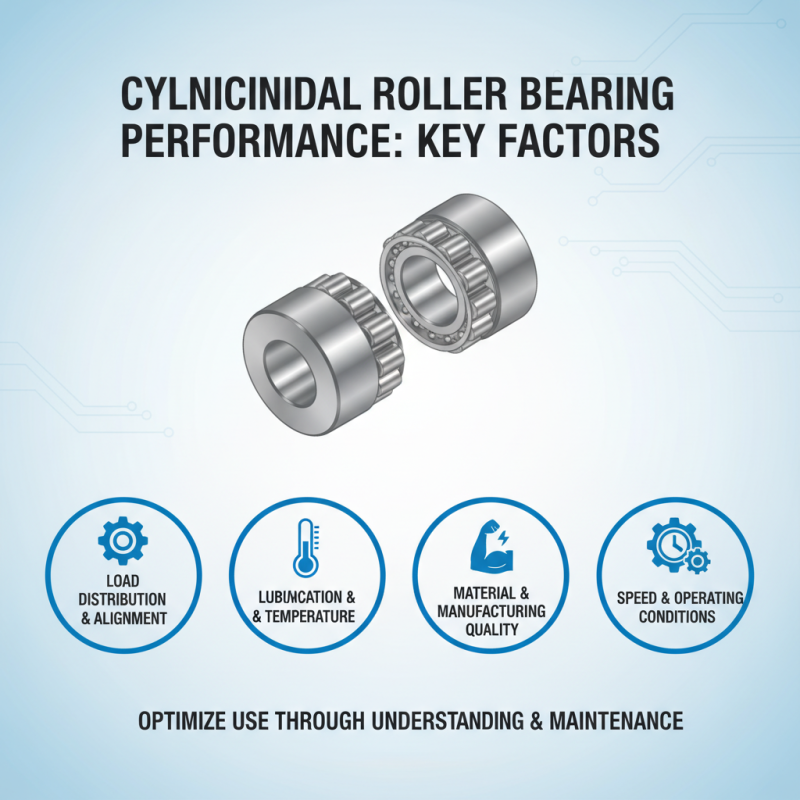

Cylindrical roller bearings are essential for various industrial applications. Their performance is influenced by several critical factors. Understanding these can help optimize their use.

One major factor is the lubrication method. Proper lubrication reduces friction and wear. Studies show that bearings with higher-quality lubricants can increase lifespan by up to 30%. However, many users overlook this. Not using the correct lubricant can lead to premature failure.

Another key element is alignment. Misalignment can cause uneven wear and vibration. Data suggests that misaligned bearings may fail up to 50% faster than well-aligned counterparts. This highlights the importance of regular maintenance checks. Users often underestimate the need for frequent inspections. Simple adjustments can dramatically improve performance.

Temperature also plays a significant role. Excess heat can lead to thermal expansion, altering tolerances. Reports indicate that operating above recommended temperatures can reduce bearing life by 40%. Many users ignore temperature monitoring, which can lead to serious issues. Understanding these factors is essential for optimal bearing performance. The industry lacks consistent awareness of these challenges.

Proper maintenance of bearing rollers is essential for optimal performance. Regular inspections can identify wear and tear before they escalate into costly failures. A study indicates that up to 70% of bearing failures are due to inadequate lubrication. This highlights the critical need for regular checks on lubricant levels and quality. Contaminated or insufficient lubrication can drastically reduce the lifespan of bearing rollers.

Furthermore, misalignment during installation can lead to uneven wear. Regular alignment checks are often overlooked yet crucial. According to industry reports, misalignment can reduce bearing life by as much as 50%. Keeping an eye on temperature can also prevent issues. High temperatures can indicate friction and lead to premature roller failure. Monitoring the operating environment for dust and debris is vital. These elements can infiltrate and damage bearing surfaces.

Despite knowing these practices, many fail to implement them consistently. Maintenance schedules can easily get pushed aside, leading to unexpected downtimes. Still, companies should invest time in training staff on proper maintenance protocols. Improving awareness can reduce common mistakes. Making maintenance a priority will ensure the reliability of bearing rollers. Adopting a proactive approach could mean the difference between smooth operations and costly repairs.

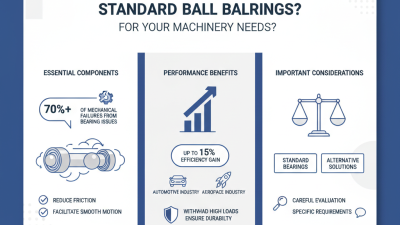

Cylindrical bearings play a vital role in various mechanical systems. They are designed to handle radial loads efficiently. Their simple design makes them cost-effective. Nevertheless, they are not always the best choice for every application. Some projects may benefit more from other bearing types, such as ball or tapered bearings. Understanding these differences is crucial for optimal performance.

When comparing cylindrical bearings with ball bearings, the former usually has a larger load capacity. However, ball bearings excel in high-speed applications. They minimize friction, making them suitable for different conditions. It's essential to assess your specific needs when selecting a bearing type. Sometimes, an ideal load capacity might not outweigh the benefits of speed and efficiency.

Tips: Always consider the environment where the bearing will operate. Dust or moisture can influence performance. Regular maintenance is essential, especially for cylindrical bearings that experience heavy loads. Lastly, keep an eye on wear and tear; it may indicate that a different type of bearing is necessary. Sometimes it’s the overlooked details that make a significant difference in performance.