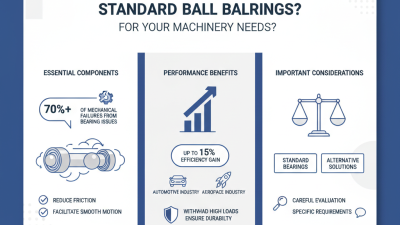

Choosing the right Deep Groove Ball Bearing is crucial for many industrial applications. These bearings are widely utilized in motors, pumps, and conveyor systems due to their versatility. According to a recent industry report, the demand for Deep Groove Ball Bearings is projected to grow by 5.8% annually until 2025. This growth underscores the importance of selecting the right bearing for performance and longevity.

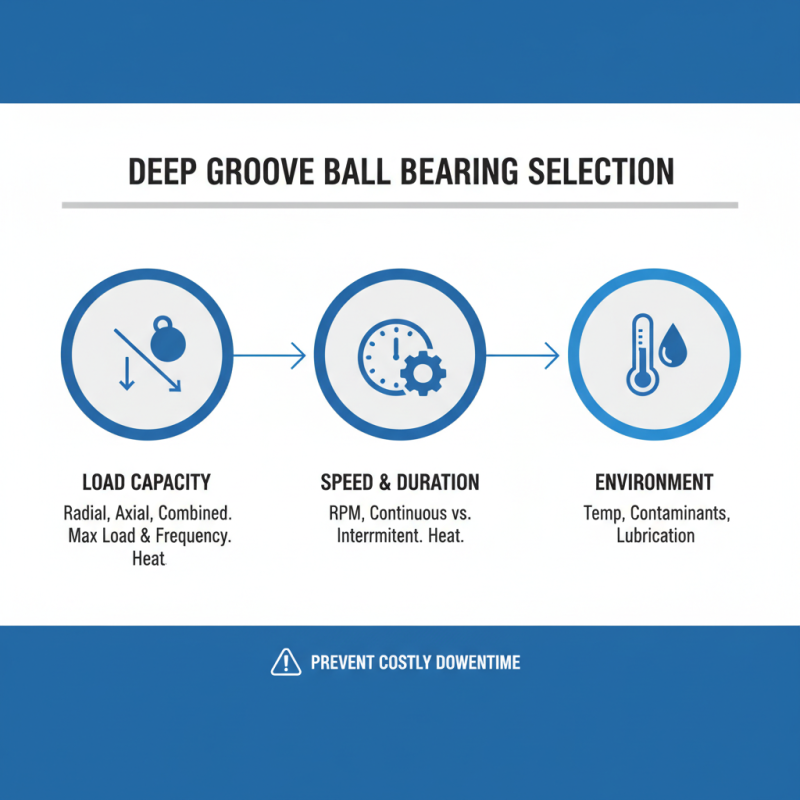

Selecting the appropriate Deep Groove Ball Bearing involves considerations like load capacity, speed, and operating environment. High-quality bearings can significantly reduce operational costs by minimizing downtime and maintenance. However, not all bearings meet the same standards. In fact, many users report issues stemming from improper selections. It’s essential to understand specific requirements and conditions to avoid costly mistakes.

Additionally, the right choice impacts overall equipment efficiency. For instance, insufficiently rated bearings can fail prematurely, leading to operational failures. Bearing manufacturers often provide specifications, but they don't always capture the nuanced needs of your application. Thus, a thorough evaluation of performance criteria is necessary for optimal selection. Investing time in this process can prevent future setbacks and improve operational reliability.

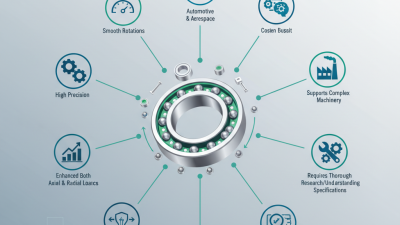

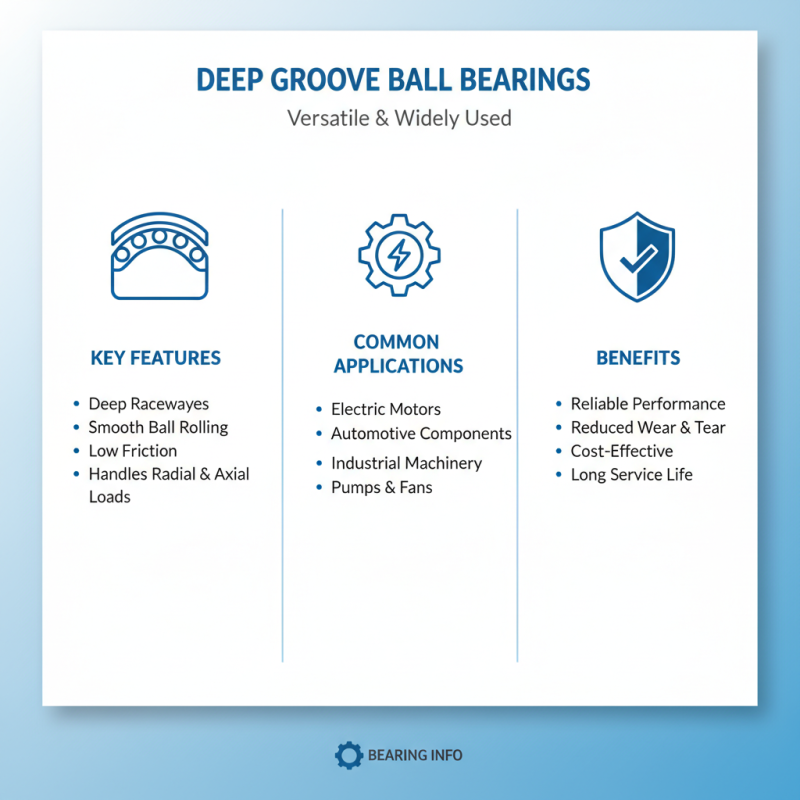

Deep groove ball bearings are some of the most common types used in various applications. They are versatile and can handle both radial and axial loads. This makes them suitable for electric motors, automotive components, and industrial machinery. The design features deep raceways that allow balls to roll smoothly, which reduces friction.

When choosing a deep groove ball bearing, consider the load requirements. Different applications may need varying sizes and materials. For instance, a lightweight application might benefit from plastic or ceramic bearings. However, these materials may not withstand harsh conditions. Steel bearings could be a better option but may add weight.

It's crucial to evaluate the environment where the bearing will operate. High temperatures or contaminated settings can lead to premature failure. Proper lubrication is another factor that must be addressed. Insufficient lubrication can lead to excessive wear. This choice should be made carefully. Understanding your specific needs will guide you in selecting the right bearing.

When selecting a deep groove ball bearing, several key factors come into play. The load capacity is critical. You need to know whether the bearing will endure radial, axial, or combined loads. Consider the maximum load and how often it will be applied. A bearing may fail if overloaded, leading to costly downtime.

Speed ratings are also essential. Check the bearing's limits to ensure it operates efficiently at your desired RPM. Higher speeds generate heat, which affects performance. Not all bearings handle heat well, so thermal resistance matters too.

Lastly, consider your environment. Is it dusty or wet? Corrosion can damage bearings quickly. In some cases, you may need sealed or shielded options. Also, think about alignment and housing compatibility. Small misalignments can result in premature wear. Always evaluate your specific needs before making a choice.

Deep groove ball bearings are essential in various applications. Their design allows for efficient operation in a wide range of environments. For example, they are often used in electric motors, automotive components, and household appliances. According to a recent industry report, the demand for these bearings is expected to grow by 6.5% annually, highlighting their widespread use.

There are different types of deep groove ball bearings, each with unique features. Single-row deep groove ball bearings are the most common. They offer low friction and can support both radial and axial loads. On the other hand, double-row deep groove bearings increase load capacity. However, they may not fit every application due to their size. The choice of bearing correlates with the specific requirements of your equipment.

Material choice also matters. Stainless steel bearings resist corrosion but can be pricier. Conversely, chrome steel bearings are more traditional but may face durability issues in harsh environments. Understanding the trade-offs is crucial. Manufacturers often overlook the maintenance needs of these bearings. Neglecting maintenance can lead to premature failure, which might cause significant downtime.

When it comes to deep groove ball bearings, lubrication and maintenance are crucial for optimal performance. Proper lubrication reduces friction, minimizes wear, and extends the bearing life. In fact, a study shows that effective lubrication can increase bearing lifespan by up to 50%.

Tip: Always consult lubrication tables that match your bearing specifications. This can greatly enhance efficiency and prevent premature failures.

Maintenance plays a vital role as well. Regular inspections help identify potential issues before they escalate. Many failures arise from inadequate maintenance practices. Even with high-quality bearings, neglect can lead to breakdowns. A report indicated that improper maintenance is responsible for nearly 30% of bearing failures.

Tip: Implement a routine maintenance schedule. This should include cleaning and replacing lubricants periodically. Each application may demand a unique approach, so adaptability is key. Regular checks and adjustments can make a significant difference in performance.

Choosing the right deep groove ball bearing is crucial for optimal performance. Many individuals overlook critical factors, leading to poor decisions. A common mistake is ignoring load ratings. Each application has unique load requirements. According to industry reports, nearly 30% of bearing failures are due to incorrect load ratings. This can be easily avoided with proper calculations.

Another frequent error is neglecting environmental conditions. Factors like temperature and humidity can significantly impact bearing performance. Studies indicate that bearings exposed to extreme temperatures often fail prematurely. Ensure to assess these conditions thoroughly. Failing to consider this can lead to unexpected downtime and repair costs.

Material selection is also often mishandled. Many users choose generic materials without considering specific needs. Specialty materials might be required for high-stress situations. Industry guidelines suggest that around 20% of bearings fail due to incorrect material choice. Failing to adhere to these guidelines can result in decreased efficiency and increased maintenance.