Bearing rollers play a crucial role in machinery and equipment. They help reduce friction and support loads effectively. Choosing the right type of bearing roller can enhance performance and extend durability.

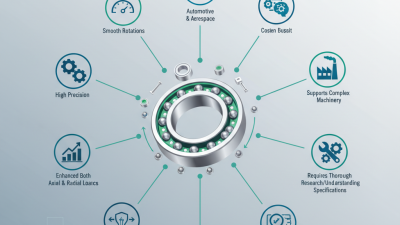

In 2026, various bearing roller types are expected to stand out. Each type has unique features that may cater to specific applications. Some options may provide high-load capacity, while others excel in speed. It is essential to evaluate the needs of your machinery before deciding.

However, not every choice guarantees success. Poor selection can lead to mechanical failures and increased costs. It’s vital to understand the working environment and application requirements. Consider factors like temperature, speed, and load conditions. Reflecting on these aspects can guide you towards the best bearing roller choice.

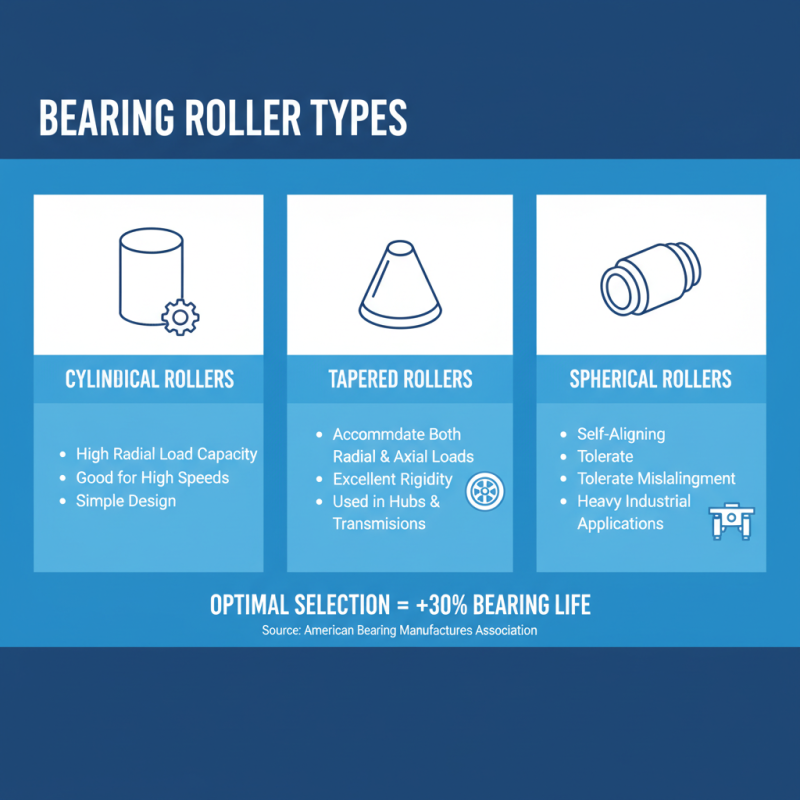

When selecting bearing rollers, it’s essential to understand the various types available. Roller types include cylindrical, tapered, and spherical. Each type has unique properties that affect performance and durability. For instance, cylindrical rollers provide high load capacity and are ideal for applications with heavy radial loads. According to a report by the American Bearing Manufacturers Association, using the right roller type can increase bearing life by 30% in some cases.

Tapered rollers, on the other hand, excel in handling both radial and axial loads. Their design allows for a higher contact surface, enhancing stability under heavy loads. The global bearing market was valued at approximately $95 billion in 2021, reflecting the growing demand for high-performance solutions. Advanced materials and coatings also play a critical role in improving roller durability. However, the increased complexity can lead to performance inconsistencies if not managed correctly.

Finally, spherical rollers offer versatility and self-aligning capabilities, making them suitable for misaligned shafts. They often perform well under varying temperature and load conditions. Nonetheless, choosing the right type requires careful consideration. Miscalculations in load ratings or application requirements can lead to premature failure. Each option has its drawbacks, and understanding them is crucial for achieving optimal performance. Balancing cost, performance, and durability is not always straightforward.

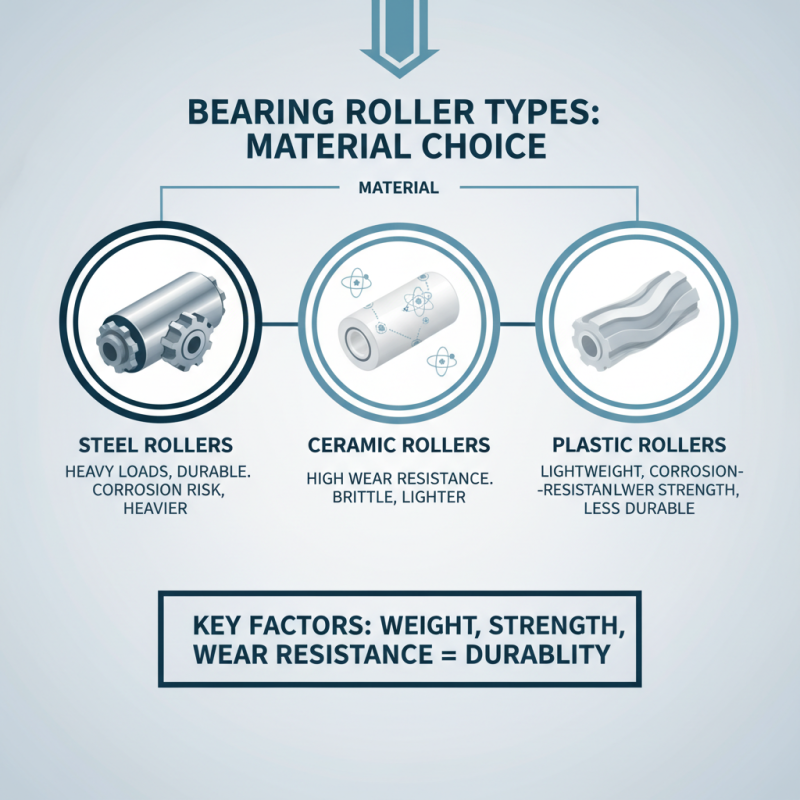

When choosing bearing roller types, several factors come into play. Material is essential. Steel, ceramic, and plastic are common options. Each material offers different benefits and drawbacks in terms of weight, strength, and wear resistance. The choice affects durability significantly. Steel rollers may last longer under heavy loads, but they can corrode. Ceramic may resist wear but is often more brittle.

The design of the roller also matters. Different shapes can influence rotation and load capacity. Standard cylindrical shapes are popular, yet spherical types offer enhanced load distribution. It's worth noting that a complex design might not equate to higher performance. Simple is often effective.

Environmental factors can’t be ignored. Temperature, humidity, and exposure to chemicals all impact a roller’s lifespan. Regular maintenance is necessary, but it also poses a challenge. Neglecting small issues can lead to major failures. Users might overlook the importance of proactive care. Understanding these factors is crucial for optimizing performance and ensuring long-lasting operation.

When it comes to selecting the right roller bearing for specific applications, understanding the differences between ball, cylindrical, and needle bearings is crucial. Ball bearings are widely used for their versatility. They excel in applications where loads are moderate and speeds are high. However, their round shape can sometimes lead to uneven load distribution.

Cylindrical roller bearings, on the other hand, offer a larger contact area. This design enables them to handle higher radial loads more effectively. Yet, they might not perform as well under axial loads, which could be a drawback in certain setups. It's important to weigh these factors when considering performance requirements.

Needle bearings serve well in confined spaces due to their slender design. They provide a compact solution while supporting high loads. However, their design can make installation tricky. Misalignment may lead to premature wear. Each type presents unique advantages and challenges, requiring careful consideration for optimal performance. Understanding these nuances can lead to smarter choices in bearing selection.

| Roller Type | Load Capacity (kN) | Speed Rating (RPM) | Friction Coefficient | Durability (Hours) |

|---|---|---|---|---|

| Ball Bearing | 15 | 5000 | 0.001 | 10000 |

| Cylindrical Roller | 25 | 4500 | 0.002 | 12000 |

| Needle Roller | 10 | 6000 | 0.0015 | 8000 |

When selecting materials for bearing rollers, several factors come into play. The choice of material significantly impacts performance and lifespan. Often, steel is the go-to option due to its strength and longevity. However, it can be heavy and prone to corrosion. Aluminum offers a lightweight alternative but may wear out faster. Composite materials present a viable solution, providing good resistance to wear and lower friction.

Each material has its pros and cons. While steel provides durability, it also requires more maintenance. On the other hand, plastic rollers can be lighter but may not hold up under heavy loads. This trade-off can lead to overloading issues. It’s essential to consider how the bearing will be used in real-life applications.

Often overlooked, lubrication plays a critical role. Applying the right lubricant can extend the life of any bearing roller. However, not all materials respond well to every type of lubricant. This mismatch can lead to performance issues. It’s vital to match the material with the appropriate lubricant for optimal results.

This chart displays the performance and durability ratings of various bearing roller types based on material selection.

Maintaining bearing rollers is crucial for optimal performance and longevity. Regular inspection is key. According to industry reports, bearing failures account for nearly 42% of machine breakdowns. This emphasizes the importance of proper maintenance. Visual checks can reveal signs of wear or contamination. Operators should schedule frequent maintenance to catch issues early.

Lubrication plays a vital role in extending bearing life. A study shows that improper lubrication can decrease bearing life by 50%. It is essential to select the right lubricant type and ensure it's applied correctly. Monitoring lubricant levels is equally important. Contaminated or degraded lubricants can lead to premature failures.

Cleaning is another essential practice. Dirt and dust can lead to increased friction and heat. A report states that up to 30% of bearing failures stem from contamination. Regularly cleaning the surrounding area can reduce this risk. Maintenance should not be overlooked, as neglect can lead to costly repairs and downtime.